Automobiles

Hyundai Motor previews new tech to beat heat waves

|

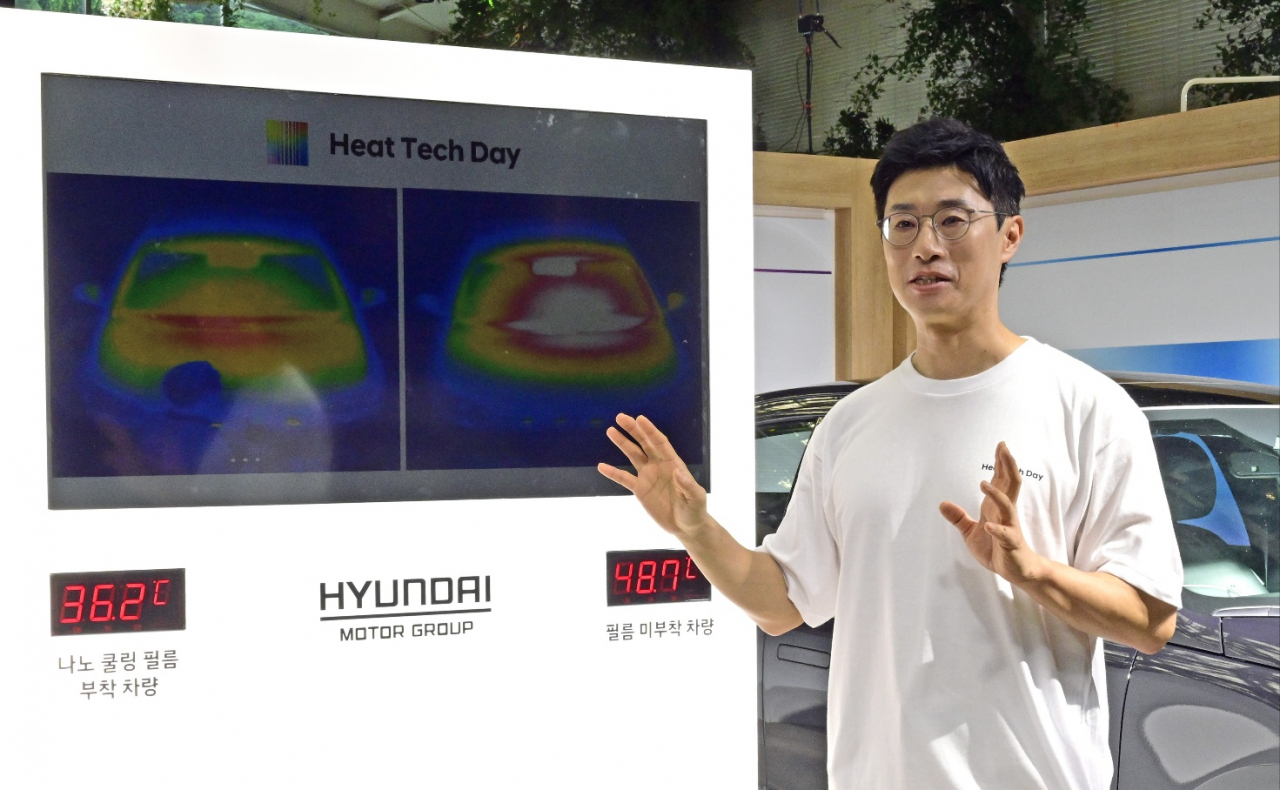

Lee Min-jae, a principal researcher from the energy component research team, explains the nano-cooling film technology on two Ioniq 6 test vehicles at Hyundai Motor Group's Heat Tech Day event on Thursday. (Hyundai Motor Group |

Amid one of South Korea’s hottest summers on record, Hyundai Motor Group hosted the Heat Tech Day event on Thursday in Seoul to preview three advanced climate control technologies to improve passenger comfort in both scorching summers and harsh winters.

The three technologies introduced at the event include a nano-cooling film that significantly lowers cabin temperatures during the summer, a radiant heating system that quickly warms passengers in winter and a metal-coated heated glass that rapidly defrosts and dehumidifies windshields while improving energy efficiency.

These technologies are still in the research and development phase and are not yet ready for mass production. Hyundai plans to integrate them into future vehicles, though the company has not disclosed a specific timeline.

|

Two Ioniq 6 test vehicles displayed during Hyundai Motor Group's Heat Tech Day show a cabin temperature difference of 12.5 degrees Celsius. (Hyundai Motor Group) |

The nano-cooling film can lower cabin temperatures by up to 10 degrees Celsius, ensuring that vehicles remain cooler even after prolonged exposure to the sun. Unlike conventional window tints, the nano-cooling film not only blocks external heat, but also dissipates internal heat.

At the Heat Tech Day event, Hyundai demonstrated the effectiveness of this film using two Hyundai Ioniq 6 test vehicles. The temperature difference between a model equipped with the nano-cooling film and one without it reached up to 12.5 degrees. Comprising three layers -- two that reflect near-infrared solar energy and one that releases interior heat -- the film can also be combined with existing window tints without darkening the glass.

|

Korean archers at the 2024 Paris Olympics wore hats featuring Hyundai Motor Group's nano-cooling film technology. The company has been a long-time financial supporter of the Korea Archery Association. (Hyundai Motor Group) |

This nanotechnology has been adapted into other forms, such as fibers. For instance, Korean archers competing at the 2024 Paris Olympics were provided with hats made from fibers embedded with the nano-cooling technology.

“In Korea, we plan to offer the nano-cooling film as an optional feature for new vehicles. In international markets, the film will be available through authorized Hyundai and Kia dealerships, with distribution handled by Hyundai Mobis, the group’s parts and services affiliate,” said Lee Min-jae, the principal researcher from the energy component research team.

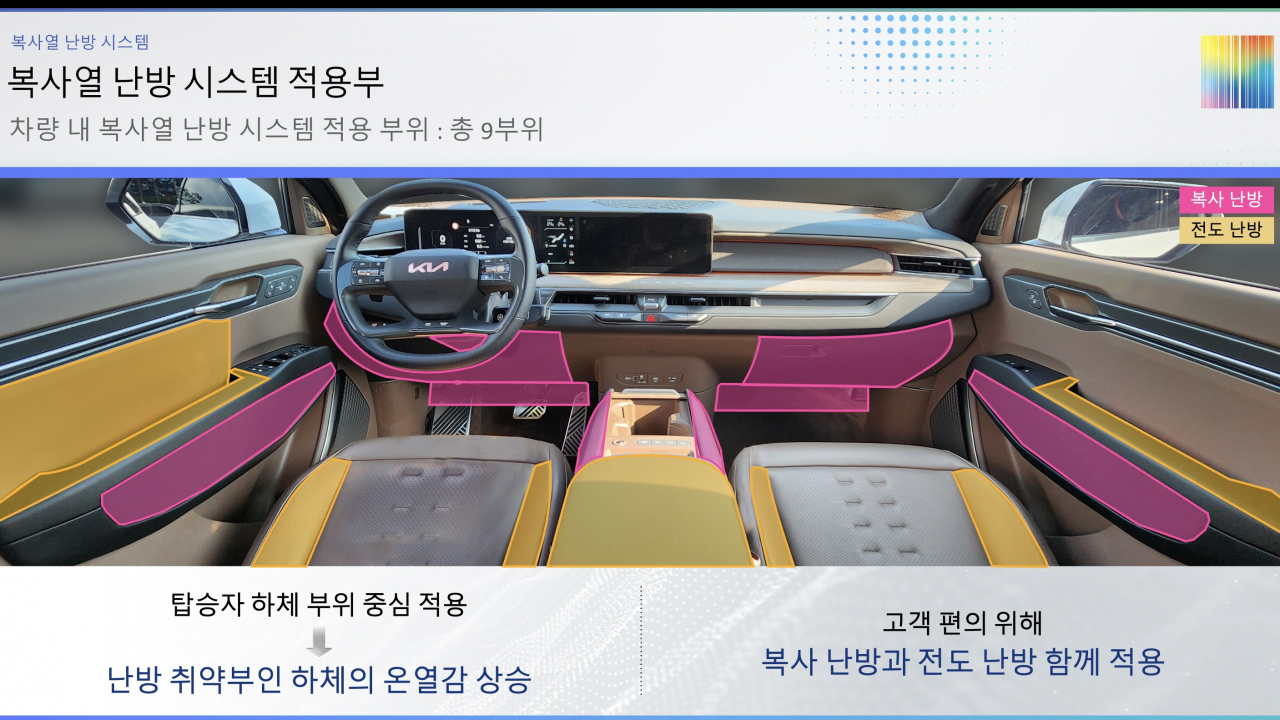

For colder climates, Hyundai introduced a radiant heating system designed to quickly warm passengers. This system, which targets the lower body area, provides warmth within three minutes, offering a more comfortable alternative to traditional air vents that blow hot air.

|

Hyundai's radiant heating system is designed to warm passengers quickly without blowing hot air directly onto the skin. (Hyundai Motor Group) |

When used alongside conventional heating systems, the radiant heating setup can reduce energy consumption by 17 percent, a critical improvement for electric vehicles, where efficiency is paramount. According to Hyundai, testing on the Kona EV revealed a 7 percent increase in driving range during cold weather, addressing a common challenge for EVs in the winter.

|

The interior of the test EV9 vehicle with the new radiant heating system is mapped out, with red marking nine radiant heating zones, such as the steering column and center console -- five on the driver’s side and four on the passenger side. Meanwhile, yellow highlights show where conductive heating keeps the seats and armrests cozy. (Hyundai Motor Group) |

The system utilizes high-temperature film-type heating elements that emit far-infrared rays, providing efficient warmth while minimizing the risk of burns. Hyundai showcased this technology in a Kia EV9 during the event, where nine heating elements were strategically placed around the cabin to maximize comfort.

|

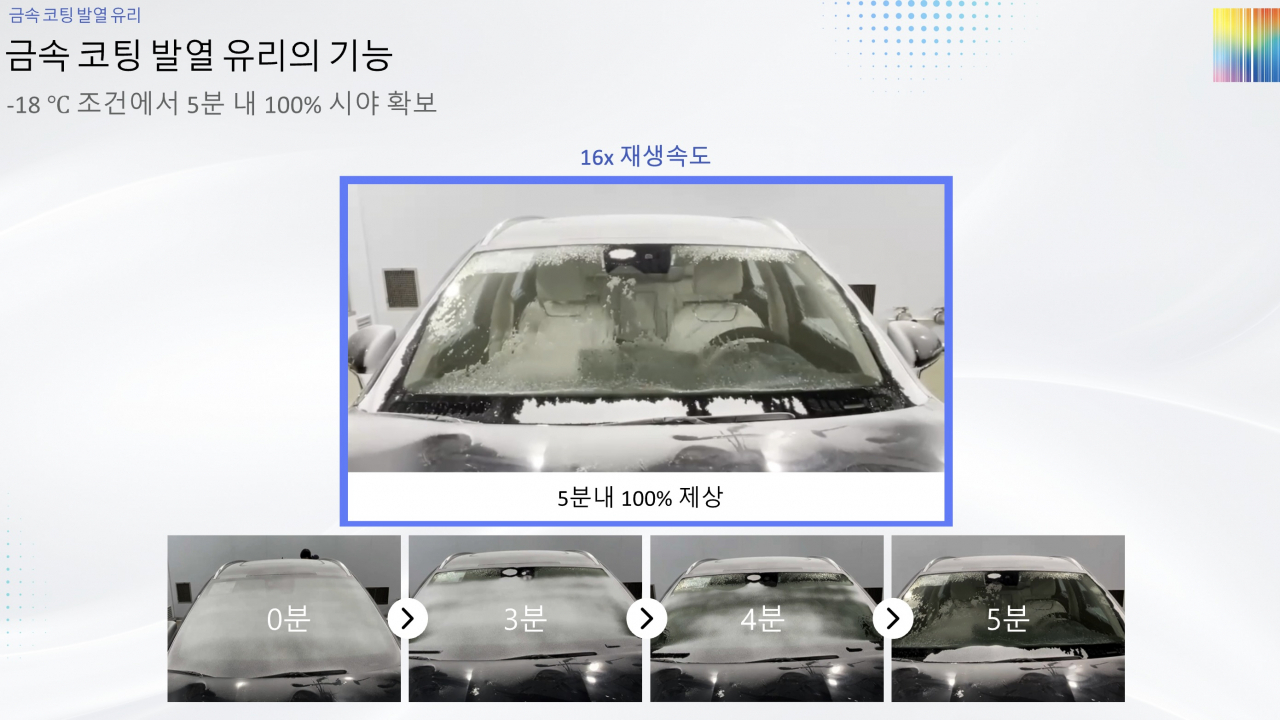

Hyundai's new 48-volt metal-coated heating glass technology can melt frost and eliminate moisture on the front windshield in just five minutes. (Hyundai Motor Group) |

Addressing another common winter challenge -- frost and fogged-up windshields -- the company introduced a metal-coated heating glass. This technology, which Hyundai claims is world-first, integrates a metal coating between laminated glass layers on the front windshield. When activated, the glass generates heat across its surface, effectively melting frost and eliminating moisture in as little as five minutes, even at temperatures as low as minus 18 degrees Celsius.

Powered by a 48-volt system that is more powerful than traditional low-voltage systems, the metal-coated heating glass defrosts the windshield four times faster than traditional methods, while consuming 10 percent less energy. This not only improves safety by ensuring clear visibility more quickly but also enhances the overall energy efficiency of the vehicle, a crucial consideration for EVs.

|

The new metal-coated heating glass warmed up at a temperature of 64.7 degrees Celcius (Hyundai Motor Group) |

The glass can also block up to 60 percent of solar rays without the need for electricity, providing a dual function that benefits drivers in both hot and cold climates. Unlike older defrosting technologies that use visible tungsten wires embedded in the glass, Hyundai’s metal-coated solution is completely transparent, ensuring an unobstructed view for the driver without visual distractions.

“This innovation could greatly improve driver safety, particularly in cold regions where clearing ice off windshields is critical. Being able to replace the old defrosting systems also gives us the chance to imagine new vehicle designs," said Jung Ki-heon, who leads Hyundai-Kia’s mid-large vehicle exterior design team 1 responsible for the metal-coated glass tech.