Tech

[From the Scene] Korean battery giants showcase new tech amid rivalry with China

|

A chassis mockup takes center stage at LG Energy Solution's exhibit to demonstrate the battery maker's new cell-to-pack technology. (LG Energy Solution) |

South Korean battery makers presented advanced battery technologies and expanded product offerings in response to the competitive pressure from Chinese manufacturers and a decelerating electric vehicle market at the Interbattery 2024 conference that kickstarted on Wednesday.

This year's event broke records, drawing an audience of 42,872 pre-registered attendees, a 77 percent increase compared to last year.

LG Energy Solution took center stage with the event's largest booth, spanning 540 square meters. A centerpiece of the exhibition was the display of the pouch-type cell-to-pack technology, demonstrated through a mockup resembling a car's chassis. This technology is designed to boost energy density and reduce battery weight and costs by eliminating the module stage. Visitors could also see its heat-reduction mechanism through green-edged heat transfer materials under the mockup car's battery lid.

"We're actively engaged in discussions with several automakers to supply our cell-to-pack technology. For all-solid-state battery tech, we’re taking the time to perfect it," said Kim Dong-myung, CEO of LG Energy Solution, who attended the company’s booth.

LG is the industry’s first company to apply this technology to high-nickel pouch-type batteries, ahead of competitors like CATL, even though CATL is developing lithium iron phosphate battery cells with an increased cell-to-pack ratio.

|

(Samsung SDI) |

Adjacent to LG, Samsung SDI presented its flagship, next-generation battery technology -- all-solid-state battery -- with a roadmap targeting the industry's highest energy density of 900 watt-hours per liter.

“Today we showcased the cutting-edge all-solid-state battery, slated for mass production in 2027. LFP batteries, currently in the pipeline too, are for 2026. The cylindrical 46mm cells will be ready and hit the market early next year," said Choi Yoon-ho, CEO of Samsung SDI, at the conference.

However, Chinese battery and car manufacturers have recently formed an alliance under a government initiative to commercialize all-solid-state batteries by 2030, involving key companies like CATL, EVE Energy and BYD's FinDreams Battery.

"South Korea definitely leads in solid-state battery technology. China government-industry alliance seems to fast-track their commercialization," said Hana Securities analyst Han Su-jin, who covers the Chinese automotive and battery sectors.

|

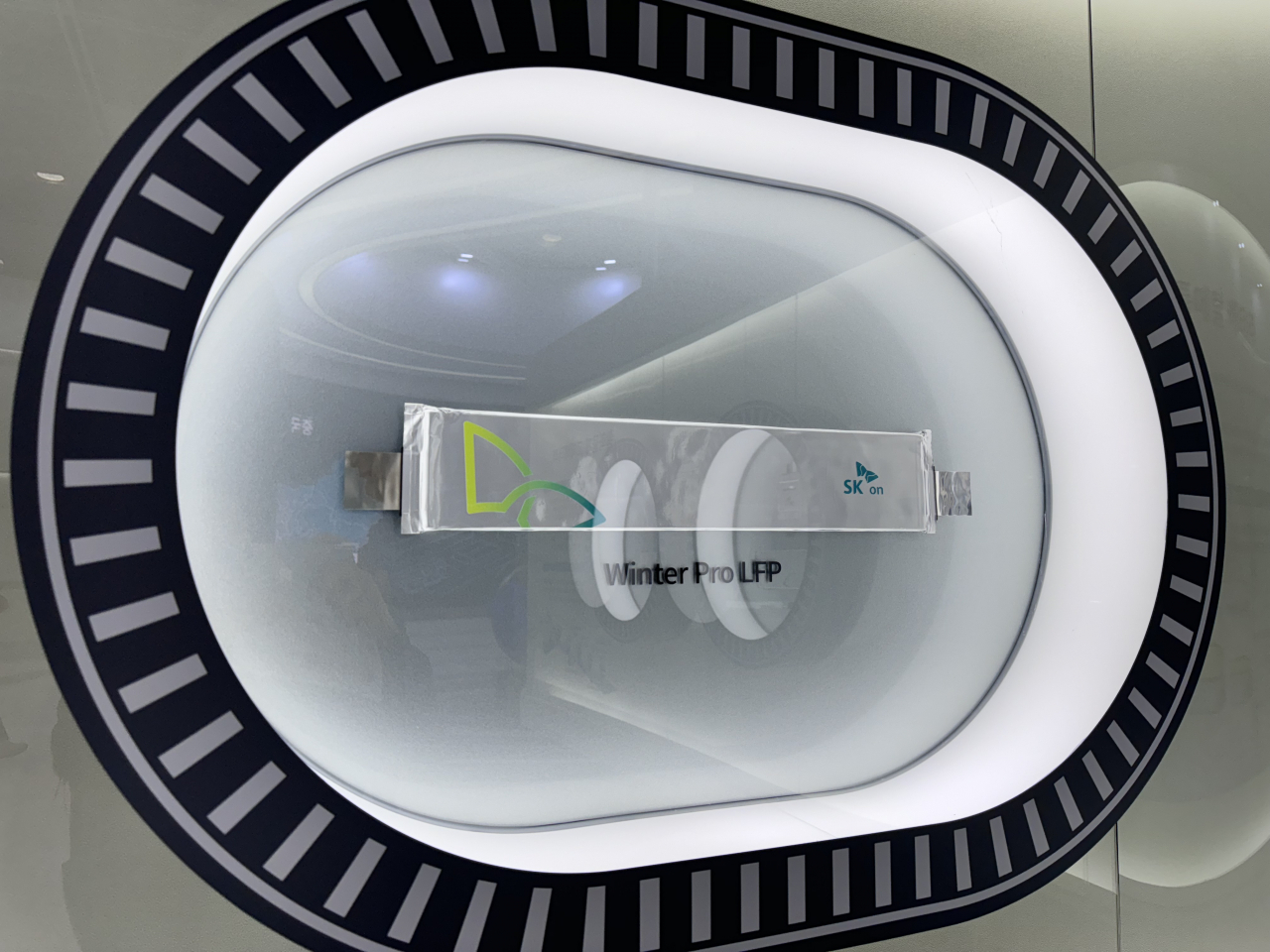

(SK On) |

SK On, another key player at the conference, introduced its Winter Pro LFP battery, addressing one of the significant drawbacks of LFP batteries -- their performance drops at low temperatures. In extreme cases, these batteries see their capacity halved at temperatures plummeting to minus 20 degrees Celsius. The Winter Pro LFP offers a solution with a 16 percent increase in charge and discharge capacity at low temperatures, along with a 19 percent improvement in energy density over standard LFP batteries.

But competitive pressure from Chinese battery makers remains high.

"China's still leading the charge for LFP batteries. Their rapid charging tech just keeps getting better as well. Take CATL's Shenxing battery, for example; it offers a 400-kilometer boost in just 10 minutes. With China's cost advantage, it remains tough for others to keep up in the LFP," said analyst Han.

SK On CEO Lee Seok-hee still expressed confidence in the face of these challenges.

"China has been a strong contender in pricing, but with our LFP battery technology now ready for mass production by 2026, we see ourselves well-positioned to make an impact in the North American market, especially as it becomes more 'blocked' due to regulations," said Lee.

|

South Korean battery supplier Kumyang's new 4695 cylindrical battery cells on display at InterBattery 2024. (Moon Joon Hyun / The Korea Herald) |

Other notable showcases included the 4695 cylindrical battery cells from Kumyang, a Korean battery supplier. This advancement in battery technology utilizes high-nickel single-crystal materials to achieve a 97 percent nickel content, significantly boosting energy density and capacity. The medium-sized company with about a hundred employees claims it boasts greater capacity than Tesla's 4680 cylindrical cells.

Developed in partnership with Korean battery tech research company SMLAB and leveraging Kumyang's proprietary technologies, this breakthrough addresses other traditional challenges associated with high-nickel batteries, such as stability and safety.

The market responded positively to this innovation, with Kumyang's stock price soaring nearly 22.81 percent on Tuesday.

By Moon Joon-hyun (mjh@heraldcorp.com)